Inadequate safety measures, limited performance, high coal consumption for power generation during unpredictable cross winds in summers and issues with anti-freezing in winters present major problems with the direct air cooling system. Longhua Technology Group has worked on these issues for over a decade and has developed a solution to optimize the direct air cooling system and the evaporative condenser system. This optimized combination has resulted in the development of a new high-efficiency condensing device - the hybrid cooler.

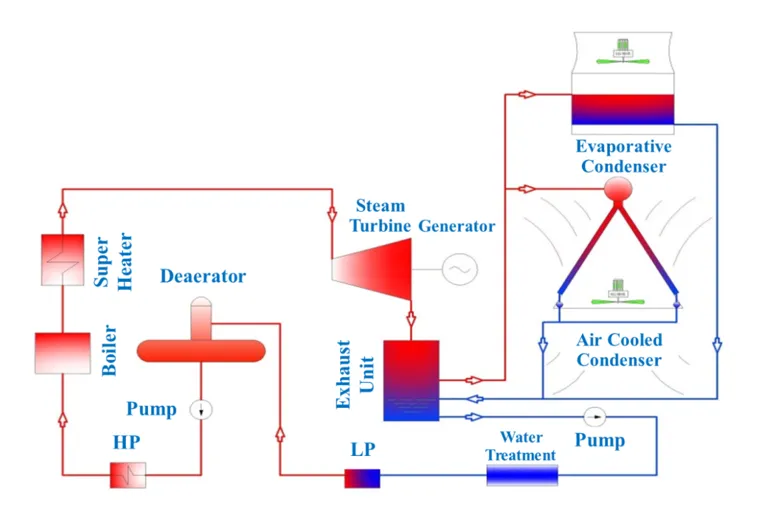

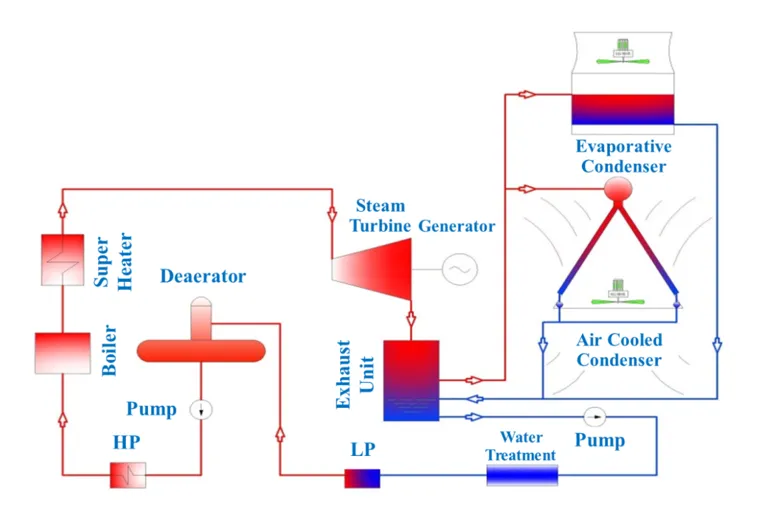

Main components

The hybrid cooler is mainly based on air-cooled heat exchange, and evaporative heat exchange is an optimization measure to reduce back pressure. Exhaust steam of steam turbine enters direct air cooling tube bundle and evaporative condenser through the main exhaust tube, and condensed water is collected in exhaust device and is sent back into system for recycling through pipeline. Non-condensable gas is pumped out and discharged into the atmosphere by the vacuum-pumping system.