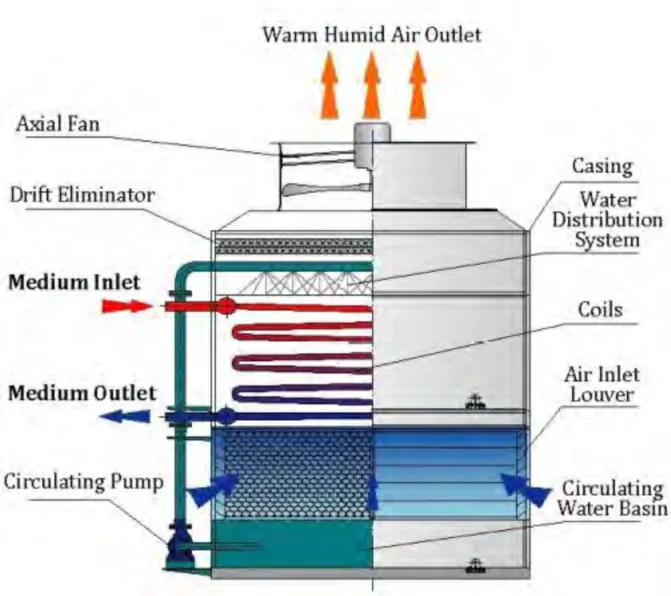

Evaporative condensers operate on the principle of evaporative cooling, where water is used as the cooling medium to remove heat from process fluids. The cooled water is then recycled and reused, making it an energy-efficient cooling solution.

The operational principles of evaporative-cooled condensers are as follows:

1. The exhaust steam of the low-pressure cylinder of the steam turbine enters the tube of the heat exchange module by condensing and releasing heat;

2. The spray water outside the pipe absorbs the condensation and exothermic evaporation of the steam in the pipe, which is discharged into the atmosphere under the action of the fan, and the water lost by evaporation is supplemented by the water supply pipeline; The unevaporated water is recycled into the water tank by the action of the water collector.

3. Condensate water is collected in the exhaust steam unit hot well through the pipeline.

4. Non-condensable gas is discharged by the vacuum device.

An evaporative condenser is typically made up of a tube bundle that is arranged in horizontal coils through which a warm fluid circulates. Water is sprayed over the tubes and evaporates, removing heat from the process fluid. The latent heat required to evaporate the water comes from the heat rejected by the process fluid being condensed. As the water evaporates, it becomes saturated with heat and is collected at the bottom of the condenser. It is then pumped to the top of the condenser, where it is sprayed again to continue the heat transfer process.

Evaporative type condensers can be used in both closed and open-loop systems, depending on the application. They are used in various industries to cool process fluids in refrigeration, air conditioning, and power generation applications. They offer several advantages, including high efficiency and energy savings, and are suitable for use in areas with limited space.