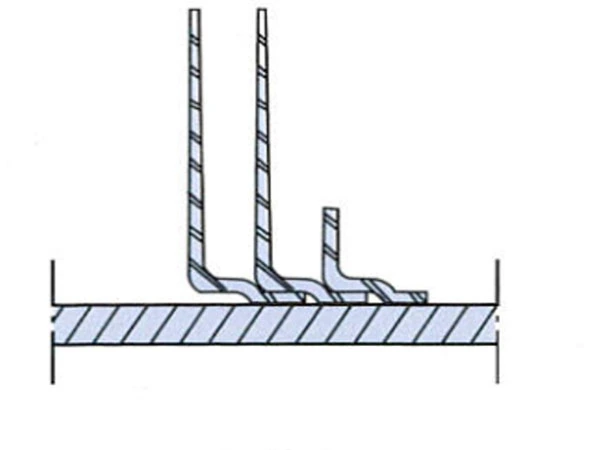

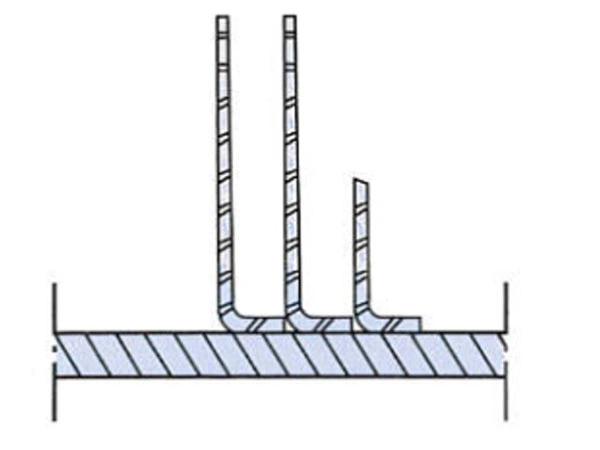

LL-Type finned tubes are one of specific finned tube types that feature a unique LL-shaped fin design. In this configuration, the fins are shaped like the letter "L" and overlap each other along the length of the tube.

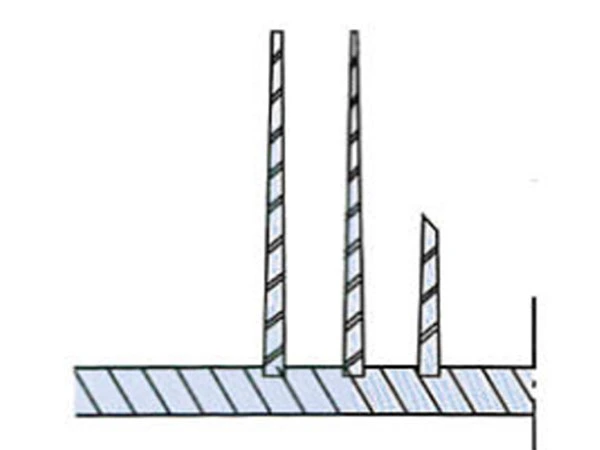

Overlapped L finned tubes find application in various industries, including power generation, petrochemical, and HVAC systems. They are commonly used in heat exchangers, air coolers, and condensers, where optimal heat transfer is critical.

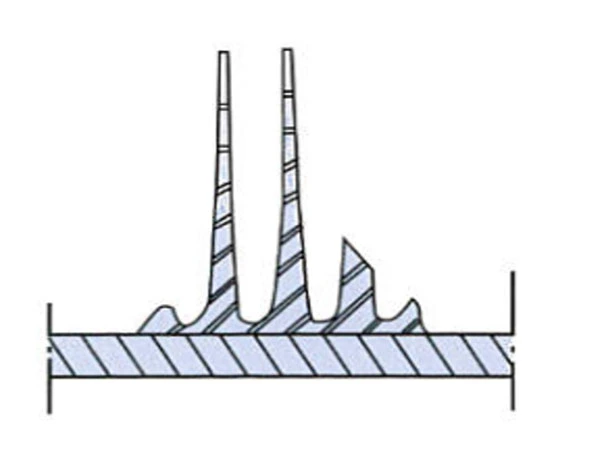

The specific dimensions and arrangements of the overlapped L fins can vary depending on the application requirements. Factors such as fluid characteristics, operating temperature, and pressure conditions influence the selection of materials, fin geometry, and fin spacing to maximize heat transfer performance.

Overall, overlapped L finned tubes provide an effective solution for improving heat transfer efficiency in thermal management applications. The overlapping fin design increases the available surface area, leading to enhanced heat exchange capabilities, improved system performance, and energy efficiency.